Dry Coolers & Air Cooled Condensers

Employing efficient design and advanced engineering, Coil Replacement Company dry cooling systems range in size from small point-of-service cooling to large and complex plant-wide systems.

Over the years, our team has experience providing services in the following industries: Aerospace, Air Compressors, Broadcasting, Casting, Cogeneration, Food Processing, Fuel Cells, Heat Treating, Machining, Petrochemical, Pharmaceutical, Plastics, Metalworking, Telecommunications and Transportation.

Product Requirement Questionnaire

Applications

CRC dry cooling systems are particularly useful in refrigeration, air conditioning, and industrial processing applications, such as free-cooling and/or the cooling of liquids that circulate inside industrial molding dies or other complex environments. For easy installation, our equipment is typically skid mounted, pre-wired, pre-piped and ready to go.

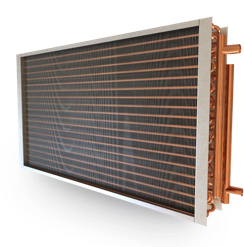

Air cooled condensers use ambient air to cool and cycle refrigerant. CRC air cooled condensers can be designed to fit practically any size workspace, and are renowned for their combination of performance, low noise emissions, and wide range of capacities. CRC manufactures these condensers for a variety of applications including, but not limited to, air conditioning, close control, refrigeration, and liquid cooling.

Air cooled heat exchangers can be used in a wide variety of applications where water is not available or when the desired outlet temperature can be achieved given the maximum ambient temperatures. This type of heat exchanger also eliminates the need for pumps, piping, chillers or cooling towers, resulting in reduced operating and maintenance costs. CRC air cooled heat exchangers are available in induced draft or forced draft configurations, as well as for vertical or horizontal airflow.

CRC integrated tower and shed systems provide all of your cooling needs in a compact, easy to manage, turn-key system. Evaporative cooling tower and shed systems provide low cost cooling below the dry bulb ambient temperature by evaporating approximately 1.5% of the flow water in order to dissipate heat and then recirculating the remainder of the cooled water through the system. Closed loop systems keep separate processes from contaminating each other, and stainless steel or fiberglass construction ensures a long operational life. These very flexible coolers can accommodate reasonably large variations in load, and the compact design allows for easy installation of new or supplemental units.

When temperatures lower than ambient are required, CRC mechanical refrigeration chiller systems provide a supply of consistent temperature regardless of the operating conditions by utilizing the compression, condensation and expansion of specialized refrigerants. Based on your specific application and regulatory requirements, we use R-134a, R-407C, R-507 and HFC 134A (non-ozone depleting) refrigerants and always produce environmentally friendly machines that meet UL, CSA, CE regulations, often qualifying for “green” tax incentives. Scroll, screw and reciprocating compressors are available, as are ethernet operated remote monitoring interface systems and easy to clean condenser filters. Our chiller systems also offer heat recuperation options, coolant storage tanks, and are capable of high pressure refrigerated pumping.

CRC fluid heat exchangers are used in applications where the transfer of heat from one fluid to another without the fluids coming into physical contact with each other is required. Fluid heat exchangers are vital when one of the fluids is contaminated, when transferring heat between different types of fluid, or between fluids at different pressures and flow rates. They can also be used to reclaim waste heat for preheating other processes or heating your work environment. Fluid heat exchangers are available in many different forms, including plate & frame and shell & tube configurations.

By extracting heat from hot waste gases, CRC heat recovery units generate hot water or steam to be used in other operations or processes such as pre-heating, rinsing, and environmental control. Our modular heat recovery units utilize waste heat and energy from industrial furnaces and ovens, power generating equipment, thermal oxidizers, turbine exhaust, and more. Removable cover plates provide easy access for inspection and maintenance, and damper controls regulate gas flow and temperature as required. These systems also qualify for many government energy efficiency incentives.

CRC has the ability to design and build any industrial pumping system to satisfy your requirements. We can meet any specification or code (CE, UL, ASME, etc.), and our systems are compatible with a varierty of fluids, temperatures, pressures and flow rates. Whether you require a closed loop, hydraulic oil, or tower water pump station, CRC has the experience and knowledge to support your needs.

CRC assigns a dedicated engineer to review, visit, measure, or consult (virtually) by analyzing your exact requirements. CRC then generates drawings, performance evaluations, and quotations – while taking responsibility for your product solution.

Unparalleled Service

We deliver unparalleled service, allowing the mechanical contractor and end-customer to focus on their core assets and property management responsibilities.

Why not give CRC a call now … and let’s work together to find the customized solution that is right for you!