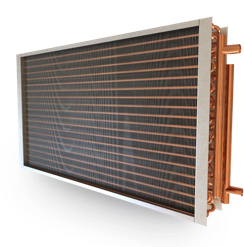

Freeze Block Coils

Coil Replacement Company is a licensed provider of Cooney Freeze Block™ Coil Technology.

Freeze damage is a leading cause of coil failure in the HVAC industry. Water expands as it begins to freeze, and the subsequent pressure builds rapidly within the coil causing the coil tubes and/or return-bends to bulge and split. Cooney Freeze Block™ Coils are designed to allow expansion to occur within the coil by discharging a small volume of water through the expansion header and integrated pressure relief valve. This patented and proven technology alleviates coil repair, downtime, and the potentially serious damage from the thaw and flood that can occur with traditional coils. Backed by a 30 month warranty, Freeze Block™ Technology is available on our booster, fluid (chilled and hot water), IFB, MODU-Coils, OEM replacement, and steam coils.

An Additional Layer of Protection

CRC is proud to also offer Cooney Smart Coil Technology. The Smart Coil combines Freeze Block™ Technology with a cutting-edge sensor to provide advanced communication with the building automation system in a compact design. Available for new and existing Freeze Block™ Coils, the sensor can be wired to send a signal to the building automation system and programmed to turn off the fan, close outside air dampers, open a valve or circulating pump, signal an audio or visual alert at the site or control room, and/or send an alert to your email or mobile device. Smart Coil Technology is backed by a 48 month warranty on new coils.

Coil Replacement Company assigns a dedicated engineer to review, visit, measure, or consult (virtually) by analyzing your exact requirements. CRC then generates drawings, performance evaluations, and quotations – while taking responsibility for your coil and/or product solution. We deliver unparalleled service, allowing the mechanical contractor and end-customer to focus on their core assets and property management responsibilities.

Long-Lasting Performance That Increases Coil Lifespan

Coil Replacement Company has mastered the art of building direct replacement coils for manufacturers including, but not limited to, Aerofin, American Standard, Bohn, Carrier, Daikin, Lennox, Magic Aire, Modine (formerly Heatcraft, Luvata), McQuay, Munters, Trane, Westinghouse, and York. In addition to the aforesaid, CRC has 100+ years of OEM engineering drawings and proprietary performance heat transfer information. CRC uses this data to properly match the size and performance of your existing coil; the goal is to make the installation process as easy as possible, meaning the coil fits and the connections are aligned with the existing piping in your facility. Contact us for assistance in selecting from our available coatings, including ElectroFin® E-coat, Endura® Coatings (750+ Technologies), Infinigard, phenolic, and UV Topcoat.

Why not give CRC a call now … and let’s work together to find the customized solution that is right for you!