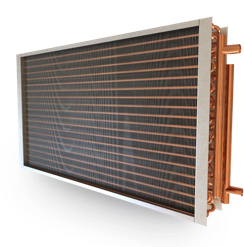

Condenser Coils

Condenser coils are essential to any HVAC system that uses refrigerant to provide comfort cooling. In DX/evaporator coils, as warm air passes through the fins and across the tubes, the liquid refrigerant inside the coil turns into a gas. It is then the job of the condenser coil to take that vapor and transform it back into a liquid.

Processes

Coil Replacement Company is able to build condenser coils for use in the following processes:

Condenser

The coil takes the superheated vapor from the compressor and cools it to saturation. It then completely condenses all of the vapor into liquid and continues to cool the resulting liquid until it reaches a specific temperature that is below saturation.

Desuperheater

The coil takes superheated vapor from the compressor and cools it down to a specific temperature that is above saturation.

Subcooler

The coil receives liquid refrigerant from a condenser and further cools the refrigerant until it is below its saturation point and at a desired exiting temperature.

Coil Replacement Company has mastered the art of building direct replacement coils for manufacturers including, but not limited to, Aerofin, American Standard, Bohn, Carrier, Daikin, Lennox, Magic Aire, Modine (formerly Heatcraft, Luvata), McQuay, Munters, Trane, Westinghouse, and York. In addition to the aforesaid, CRC has 100+ years of OEM engineering drawings and proprietary performance heat transfer information. CRC uses this data to properly match the size and performance of your existing coil; the goal is to make the installation process as easy as possible, meaning the coil fits and the connections are aligned with the existing piping in your facility.

CRC assigns a dedicated engineer to review, visit, measure, or consult (virtually) by analyzing your exact requirements. CRC then generates drawings, performance evaluations, and quotations – while taking responsibility for your coil and/or product solution. We deliver unparalleled service, allowing the mechanical contractor and end-customer to focus on their core assets and property management responsibilities.

Long-Lasting Performance That Increases Coil Lifespan

To ensure long-lasting performance while increasing the lifespan of your replacement condenser coils, CRC offers many different coating options that provide an additional level of protection against corrosive environments including, but not limited to, automotive paint houses, chlorinated pool facilities, coastal sea areas, industrial manufacturing plants, locations with high sun exposure, medical/pharmaceutical environments, and restaurant kitchens. Contact us for assistance in selecting from our available coatings, including ElectroFin® E-coat, Endura® Coatings (750+ Technologies), Infinigard, phenolic, and UV Topcoat.

Why not give CRC a call now … and let’s work together to find the customized solution that is right for you!